An essential product with an outdated design

The genesis of EDJY

We’ve all spent our entire lives with a nail care routine that involves:

- Finding a quiet space to trim our nails without bothering those around us.

- An annoying process of trying to collect and clean the clippings that fly everywhere.

- Ending up with jagged nails that you need to repair with a file.

Old-fashioned nail clippers do the job, but they don’t do it well.

Enter EDJY. Our founder, Jake Peters, spent the last 15 years asking one question: Why not make this essential, everyday product WAY better? We weren't content to make small improvements. Instead, we went back to the drawing board and hired six engineers and two metallurgists to completely rethink and redesign the nail cutting process.

Our foundational principles were simple: create a product that is easy to use, cleanly cuts your nails, avoids flyaways, lasts multiple lifetimes, and is MADE IN THE USA.

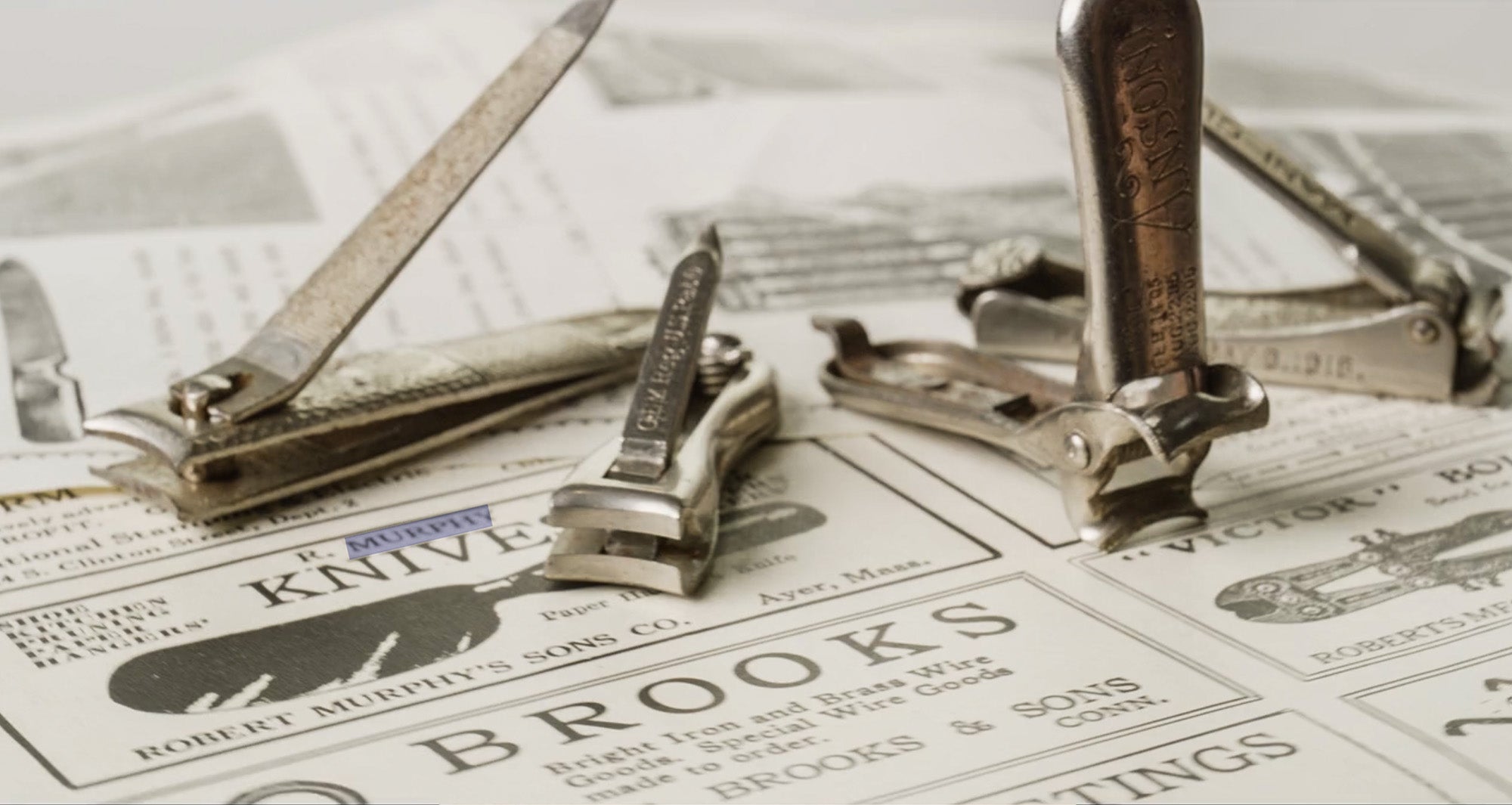

We embarked on an exhaustive evaluation of the nail clippers available on the market. Our goal? To truly understand the mechanics and why these products failed to meet expectations. We went to work. We analyzed how the mechanisms function and how the materials and blade designs impact their effectiveness. It may be the most comprehensive study of nail clippers ever undertaken. This is the most engineered, best performing nail cutter ever made.

An exhaustive review of the market

Starting from scratch

We bought every nail clipper that we could find. We wanted to see how they worked, what was good, what was bad, and how we could improve on the current designs.

Our realization

The two-blade problem

Nail clippers are fundamentally flawed. They use two blades (jaws really), actuated by a lever (which works great), to clip through your nail. Sounds simple, right? Wrong. Using high-speed cameras and microscopes, we saw how traditional clippers simply crush your nail's keratin, building up so much force that the nail fractures. That built-up energy causes the nail to fly away and leaves the end of your nail with a jagged surface. We find it amusing that they then provide you with a flimsy nail file to repair the damage done by the underlying device.

Some better clippers offset the blades slightly, but the blades still smash together (or bend the blade), resulting in the same rough surface. Sharper blades might seem like the fix, but they dull or bend just as quickly as the two blades hit each other over time.

Short-cutting your nails

Crushing your keratin

Though there were some subtle differences, every clipper on the market shares the same problem.

They use two blades to try to cut your nail, the end result is always that traditional clippers crush or tear your nails.

Our revelation

A single-blade solution

We realized that to build a better product, we needed a single blade.

Our single sharp blade cleanly cuts through your nail, leaving a smooth edge and eliminating the stored-up energy that sends clippings flying. This revelation became the foundation of the entire product design.

Traditional nail clippers rely on a powerful lever to compensate for their subpar design, applying sheer force to push the cutting edges through your nail.

Our blade improvement allowed us to rethink the overall design.

The rest is fundamental

While the single blade was the guiding principle behind our design, we strongly believe that in order for a company to actually make a difference in the lives of its consumers, we have to be responsible stewards. This means not only delivering a high-quality product but also ensuring that our business practices are ethical and sustainable.

Our pillars of value, sustainability, and American manufacturing are fundamental to our Company. We are committed to using environmentally friendly materials, reducing waste, and supporting local economies. By adhering to these principles, we aim to create a positive impact that extends beyond just our products and into the wider community.

Value and sustainability

Nail cutters shouldn't be disposable. Our cutters are designed to last a lifetime (several actually). We custom-built a testing machine to cycle our cutter over 150,000 times to ensure durability and edge retention.

Every detail matters

In order to make a product that lasts a lifetime you have to obsess over every detail. We spent over a year testing stainless steel formulas and resins, and went through dozens of design iterations until we reached the final design. We electropolish our blades to achieve the highest possible corrosion resistance and run EDJY Nail Cutters through a four step ultrasonic cleaning process to remove any contaminants from the manufacturing process. We sweat every detail because we know the proof isn't in the first cut, but the one 50 years down the road.

100% MADE IN THE USA

While many companies move production overseas for cost savings, we believe in keeping it local. Our factory is just outside Detroit, with all our suppliers within a 250-mile radius. This reduces emissions and supports our local economy.

The result

A cut above

At EDJY, innovation is in our DNA. We built the world's first single-blade nail cutter based on exhaustive research and intuitive design. Every aspect of our product—from the materials to the manufacturing process—focuses on quality, performance and longevity. You'll feel the difference from the minute you open the box.